Technological improvements

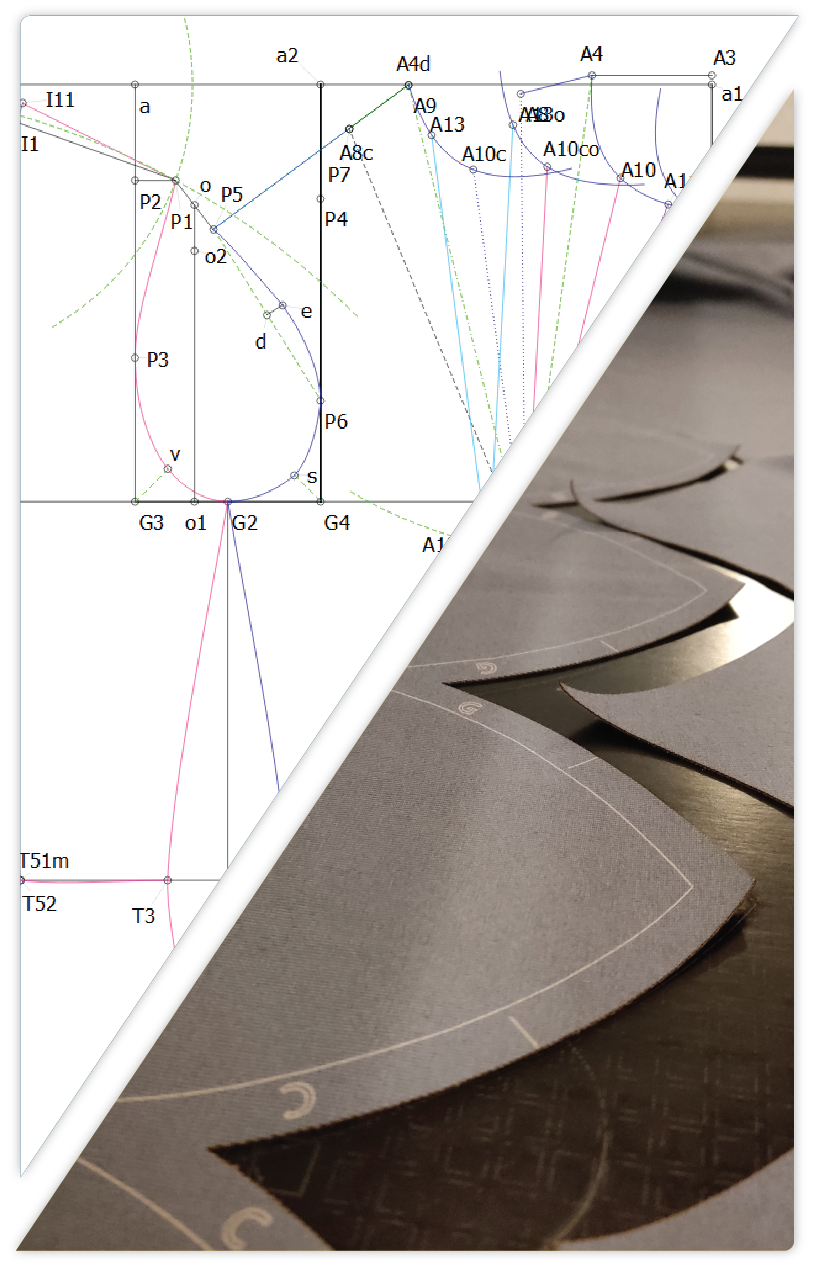

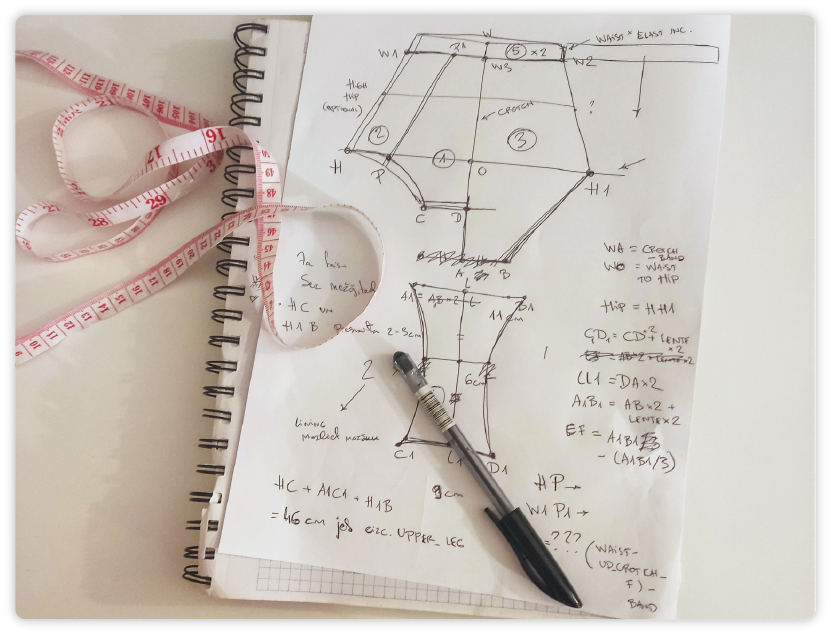

Previously, we relied on manual pattern-drawing techniques, attempting to adjust and scale patterns to suit our various needs and sizes. However, we soon realized that this approach was not the most efficient or accurate. Thus, we made the switch to digital parametric formula-based modelling system, recognizing its potential to improve our pattern making process allowing precise adjustments and scalability. Precisely what we needed. While transitioning to this new tool wasn't without its challenges, requiring extensive training courses to master, the investment has proven worthwhile. Now, we can ensure that each of our garments is customizable to fit the sizes and preferences of all of us effortlessly. And it's digital. Meaning that we could integrate that in something else

directly.

And that something else is cutting and marking the fabric. Frustrated by the errors and imprecision that often arose from manual fabric cutting using templates, crayons and scissors, we sought alternative solutions to ensure the accuracy and quality of our kits. The desire to streamline our processes through automation was evident, but we were wary of bulky, industrial-scale machinery that wouldn't fit into our cozy sewing workshops.

Our search focused on fulfilling several key criteria: the ability to cut and mark various fabric types accurately, catering to typical garment sizes, seamless integration with our digital patterns, all while still to fit in one of our workshops. That resulted in building our own computer driven fabric cutting and laser etching machine allowing to cut the fabric in size up to 1.5 square meters and draw on it.

Now, our output matches the precision modeled in our designs – every cut and mark is executed with sub-millimeter accuracy. By optimizing the placement of fabric pieces, we've significantly reduced waste. Importantly, this process is repeatable, ensuring that we can produce exact garment parts consistently, no matter how many times they are replicated.

It takes much to be sure about the quality of patterns and technological processes - how scaling will impact, are there any mistakes, communication between equipment, fabric properties, equipment adjustment etc. Each new idea is tested as much is needed. When a new product is accepted as fair enough (nothing is perfect and never is ready), it is time to finish the pattern itself, prepare all sizes, detail all instructions for you and finally let it go to!

It takes much to be sure about the quality of patterns and technological processes - how scaling will impact, are there any mistakes, communication between equipment, fabric properties, equipment adjustment etc. Each new idea is tested as much is needed. When a new product is accepted as fair enough (nothing is perfect and never is ready), it is time to finish the pattern itself, prepare all sizes, detail all instructions for you and finally let it go to!